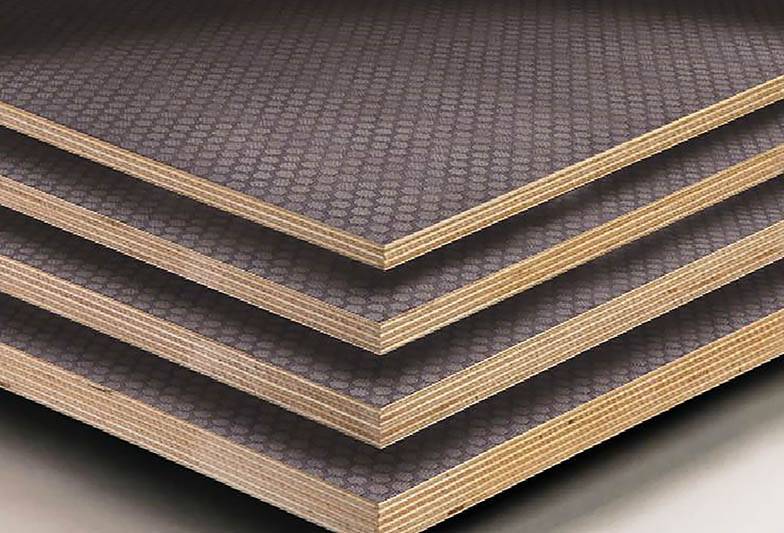

Plywood Laminated (Weather and Boil Proof – WBP) 15*1220*2440 mm – for pre-order only!

Please email us for placing the order/ This item is currently only available for pre-order. Although we appreciate custom requests, please note that we cannot fulfill orders in small quantities as it is exported from Europe, Minimum order quantity: 1 x 40 ft container. Terms of delivery: FCA .

📞 Call us: 0447 764 768

📧 Email us: uk.oxleytrade.com.au@gmail.com

Number of pieces in a pack : 26

Surface laminated, smooth

Type moisture resistant

Note: This item is currently only available for pre-order. Although we appreciate custom requests, please note that we cannot fulfill orders in small quantities as it is exported from Europe, the minimum order quantity is a container.

The internal volume of a 40-foot container is 67.3-67.8 m3.

The maximum carrying capacity is 24.8-26.8 tons.

The weight of a 40-foot container without cargo is 3,640-4,000 kg.

Exterior and Interior Birch Plywood and Film Faced Plywood is a high-quality construction material with high durability and moisture resistance. This product is FSC or PEFC certified. Plywood is a sheet building material used in construction and furniture making. It is a manufactured product, made by gluing thin layers of wood veneer together.

2440mm x 1220

Thickness (mm) 7 10 12 15 18 21

Number of layers 7 11 13 15 19 23

Divergence, mm 5 7 9 11 13 15

Additionally marine grade plywood possesses the following advantages:

* Higher resistance to mechanical failure and wear

* High durability in folding and ripping

* High water-resistance

* Ability to remain its operational characteristics in humidity and temperature changes

* Ease of handling

* Convenience in processing

* Perfect compatibility with other building materials

Characteristics of Marine grade plywood

* Is made from birch veneer of 3 grade, glued together in mutually perpendicular direction of fibers with glue based on resin Prefer 14J for FBV;

* Internal layers go through a joint making line;

* External layers go through the line of rib gluing.

* Thickness of plywood: 7-21mm

* Shear strength on the adhesive layer after boiling for 2 hours – not less than 1,76Mpa

* Size 1220x2440mm

* Tensile strength along outer layers’ fiber direction, not less than: for thickness 7mm – 88,0 MPa; for

* Thickness 10,12,14,16 mm -73,5MPa

* Static bending strength, not less than: across outer layers’ fiber direction – 78,5 МPа, along outer layers’

* Fiber direction – 117,5 МPа

* Shear strength on the adhesive layer after boiling for 2 hours – not less than 1,76Mpa

* Density not more than 1200 Kg/m3

* Formaldehyde emission class E1

Reviews

There are no reviews yet.